- Always focus on profitability. Pricing should never be “off the cuff.” Your small business should have a pricing structure that fully supports costs and expenses, including profits. Can you imagine a business without profitability? It is simply impossible!

- Researching the market is essential to starting any new enterprise, but starting off by averaging what the competition charges is not a sustainable business model. A price list should be based on your business, not your competitors!

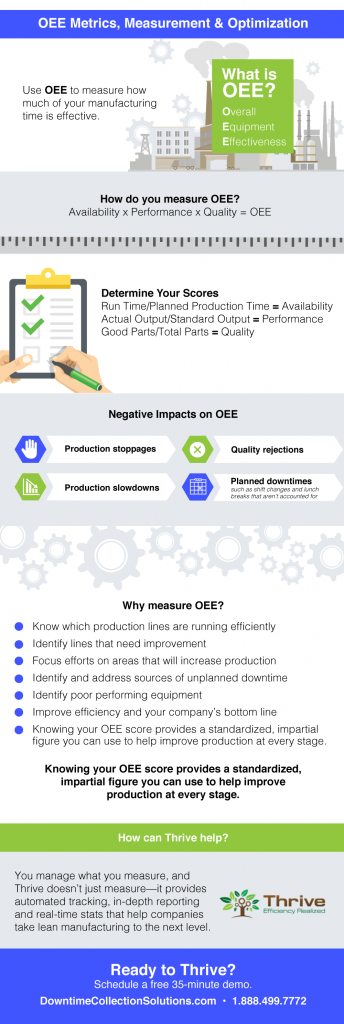

- Take all of your expenditures (even the hidden ones, like prep and finishing) and make sure your business’ floor plan is laid out for maximum efficiency. Then, start measuring realistic production times. Take a stopwatch if you have to.

- Crunch all the numbers, using times for typical yield based on actual production, and have a pricing structure that balances the numbers properly. One goal could be to get flat-rate pricing that covers all expenses, with the right profit built-in.

- The main thing to keep in mind is you got into the embroidery business to make money. With a little planning and using these four tips, your shop can grow steadily and remain profitable.

- When machines stop, so do profits. This is why there should be a variety of projects, with both low and high profit margins. Having the occasional high-volume/low-margin project intermixed with several high-profit, yet small-quantity jobs will keep your progress steady and manageable.

The triple bottom line is one of the principles of sustainable business that gives weight not just to making a profit, but also to being responsible for how a business impacts people and the planet. In short, it looks at people, planet, and profit in all business considerations.

The triple bottom line is one of the principles of sustainable business that gives weight not just to making a profit, but also to being responsible for how a business impacts people and the planet. In short, it looks at people, planet, and profit in all business considerations.

You may have a gut feeling that your business is humming along smoothly — and you might be spot on. But there is no substitute for concrete numbers when it comes to measuring your business’ financial health. That’s where financial KPIs — key performance indicators — come in. KPI is a blanket term for the types of markers that businesses use to measure performance in a variety of areas, from marketing to HR to finance. Keeping close tabs on your small business’ financial performance is essential to long-term success. These financial KPIs will help you answer the question: Is my business meeting its goals?

You may have a gut feeling that your business is humming along smoothly — and you might be spot on. But there is no substitute for concrete numbers when it comes to measuring your business’ financial health. That’s where financial KPIs — key performance indicators — come in. KPI is a blanket term for the types of markers that businesses use to measure performance in a variety of areas, from marketing to HR to finance. Keeping close tabs on your small business’ financial performance is essential to long-term success. These financial KPIs will help you answer the question: Is my business meeting its goals?