How does Thrive work?

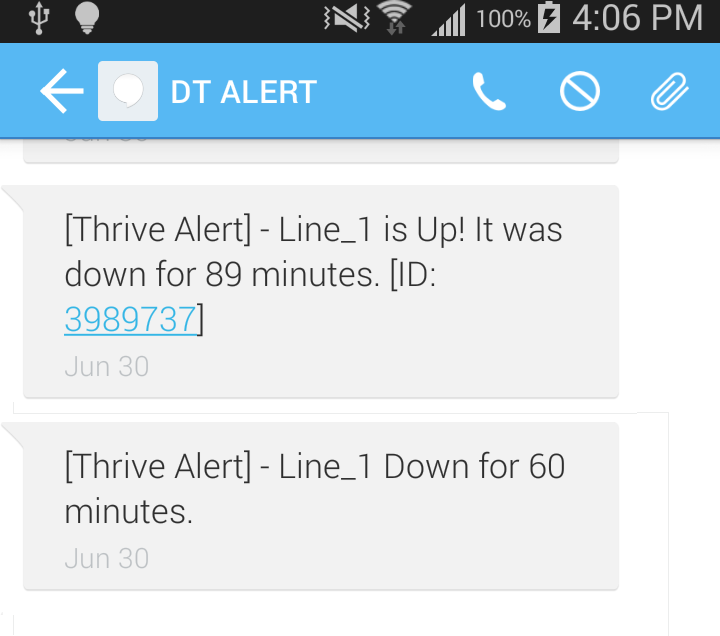

Thrive’s cutting-edge plug-and-play hardware is designed to monitor the heartbeat and output of your manufacturing lines, providing real-time equipment performance tracking. This means you’ll have immediate insights into whether your lines are operational, how efficiently they’re running, and where you can implement strategies to reduce production downtime. By delivering actionable data, Thrive helps to optimize OEE (Overall Equipment Effectiveness) and enhances productivity through advanced automation and comprehensive performance analysis.

Take a tour of our innovative solutions, and discover how Thrive empowers manufacturers to achieve greater efficiency. Contact us today for a quote to see how affordable and impactful our software solutions can be. | Explore Thrive’s How-to Videos to learn more about improving your plant’s operational performance.

Wired or Wireless Installation

Wired or Wireless Installation  Real-Time Production Status

Real-Time Production Status  Dashboard

Dashboard  Operator Friendly

Operator Friendly  Reason Codes

Reason Codes  Daily Digest

Daily Digest  Export Your Data

Export Your Data  Monitor from Anywhere

Monitor from Anywhere  Wired or Wireless Installation

Wired or Wireless Installation